Brake Hoses

Characteristics

Hose technical aspects SAE J1401 FMVSS 106

- Inert Gas Test: 105,3KGR/ X 3 MIN

- Test with Liquids: 211 KGR/CM3 X 3 MIN

- Resistance Hydraulic Pressure: 251 KGR / CM3

- Dynamic Torsional Strength: 36 Horas Non-Stop

- Tensile Strength: 1446 KGM

- Ozone Resistance: No cracking under 7MM lens

- Salt Chamber: Extreme corrosion resistance

- Volumetric Expansion Test: 0 Volumetric Expansion

- Final Hydraulic Resistance Test: 3650 PSI for 25 Seconds

Levels of Quality

Hose J1401

Built in compliance with the J1401 standard, but with different quality arguments in terms of durability and strength with reinforcements:

- Superior Quality: Nylon – Nylon

- Medium Quality: Nylon – Cotton

- Low Quality: Cotton – Cotton

Advantages

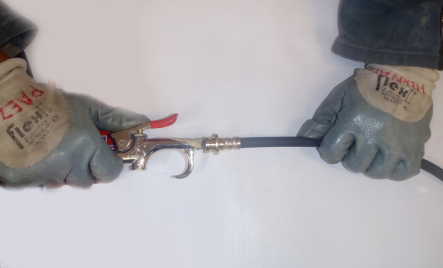

Cleaning

Consists of passing high-pressure air through the hose to remove dust particles or foreign elements, leaving it 100% clean.

Protection

These are plugs that are placed on the hose to avoid contamination by dust, providing total protection.

Quality Verification Seal

After all these processes, each hose is given a final review and, if the product is 100% safe and of optimum quality, a label is placed on it indicating that it is ready to be packaged.

Tube Verification

A manual inspection of each hose is carried out, verifying with wire that is not obstructed.